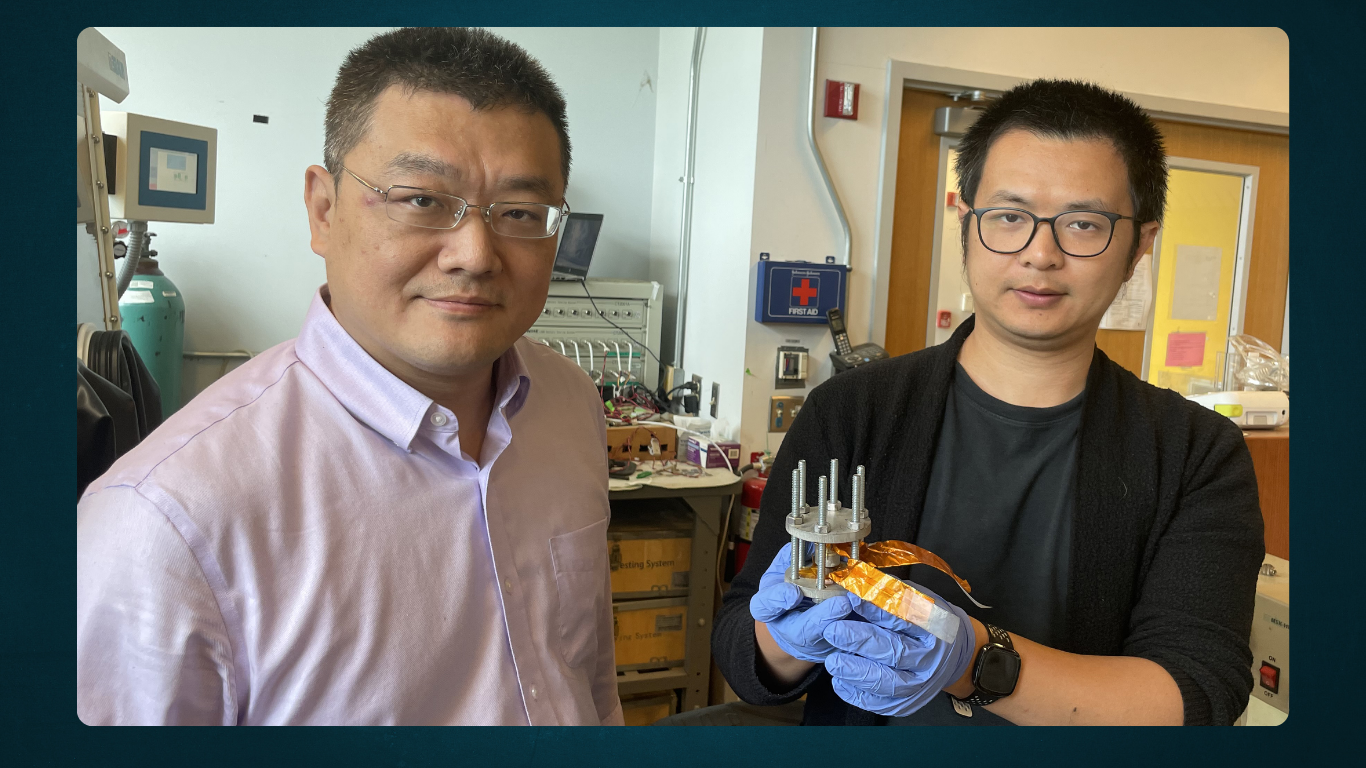

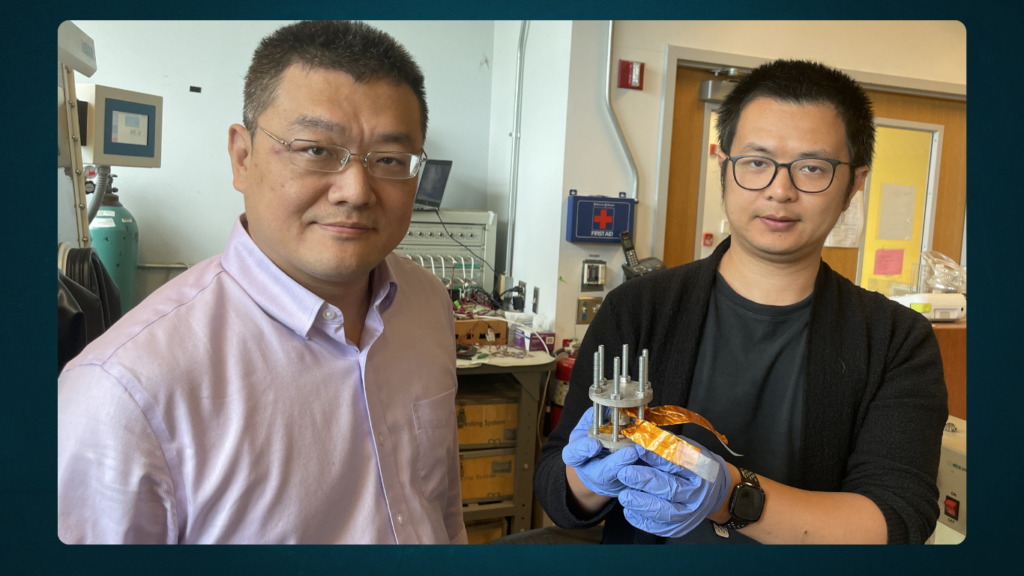

A multi-institutional team of researchers, led by Hailong Chen from Georgia Tech, has unveiled a breakthrough in lithium-ion battery (LIB) technology that could reshape both the electric vehicle (EV) industry and large-scale energy storage. The team’s newly developed low-cost cathode could significantly reduce the price of LIBs while maintaining their efficiency, offering a potential revolution in energy storage solutions.

Currently, the high cost of LIBs—particularly the expensive metals used in their cathodes—is a major barrier for the EV market, where battery packs account for up to 50% of the vehicle’s cost. Chen’s innovative cathode material, made from iron chloride (FeCl₃), is a fraction of the cost, priced at just 1-2% of the current cathode materials, yet offers equivalent energy storage capabilities.

“For years, we’ve been searching for an alternative to expensive cathode materials, and we believe FeCl₃ could be it,” said Chen, an associate professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering at Georgia Tech.

The new cathode could pave the way for all-solid-state LIBs, which represent the next frontier in battery technology. Traditional LIBs use liquid electrolytes to transport lithium ions, which limits their energy storage potential and poses safety risks like leakage and fires. Solid-state batteries, however, use solid electrolytes, providing increased safety, higher energy densities, and better overall efficiency.

The Evolution of Lithium-Ion Batteries

Lithium-ion batteries, first introduced in the 1990s by Sony, revolutionized the world of personal electronics, powering devices like smartphones and tablets. Over time, they became the preferred energy source for electric vehicles due to their high energy density and rechargeable nature. But while LIBs offer significant advantages over older technologies like alkaline and lead-acid batteries, their reliance on expensive metals, such as nickel and cobalt, drives up the cost.

Only four types of cathodes have been successfully commercialized for LIBs to date. Chen’s FeCl₃ cathode would be the fifth, and it could represent a major leap forward by enabling the development of more affordable solid-state batteries. With its iron chloride cathode, solid electrolyte, and lithium metal anode, the new battery design developed by Chen’s team could reduce manufacturing costs by 30-40% compared to current LIBs, making electric vehicles more accessible and cost-competitive with gasoline-powered cars.

“This could fundamentally change the landscape of the EV market and offer new possibilities for large-scale energy storage, contributing to a more resilient electrical grid,” Chen said. Additionally, by using abundant and inexpensive elements like iron and chlorine, the FeCl₃ cathode is far more sustainable than the nickel and cobalt found in existing LIB cathodes.

Building a Sustainable Future

The development of this cathode is rooted in Chen’s earlier work on solid electrolytes, which began in 2019. His team initially tested chloride-based solid electrolytes alongside conventional commercial cathodes, but the materials proved incompatible. This setback led the researchers to explore chloride-based cathodes, which eventually brought them to iron chloride.

“We found FeCl₃ to be a promising candidate for lithium-ion storage and transport due to its crystal structure, and fortunately, it performed just as we had hoped,” Chen said.

FeCl₃’s potential to outperform conventional cathode materials was confirmed in early tests. Not only does it operate at a higher voltage than lithium iron phosphate (LiFePO₄), one of the most widely used cathode materials today, but it also provides a cleaner and more sustainable option for EV batteries. In contrast to nickel and cobalt, which are expensive and pose environmental concerns, iron and chlorine are abundant and easily accessible, making FeCl₃ a more attractive alternative for manufacturers.

A Game-Changing Development

The impact of this breakthrough could extend well beyond the automotive industry. Large-scale energy storage systems, which are essential for renewable energy grids, could also benefit from the lower costs and improved performance of FeCl₃-based batteries. As the global demand for energy storage continues to grow, the need for affordable, efficient, and safe batteries becomes even more pressing.

The research team, led by Chen and postdoctoral researcher Zhantao Liu, includes collaborators from Georgia Tech’s Woodruff School, the School of Earth and Atmospheric Sciences, Oak Ridge National Laboratory, and the University of Houston. They are now focused on refining the material and scaling up the technology for potential commercial use within the next five years.

“We’re working to perfect the cathode in the lab, and we’re also exploring opportunities to scale it up for industrial applications,” said Chen. “We’re optimistic that this could help drive down the cost of EVs, making them more affordable than internal combustion cars, and offer a new, resilient form of energy storage.”

Pathway to Commercialization

While the FeCl₃ cathode is still in development, it holds significant promise. The team’s focus is on understanding the material’s mechanisms and improving its properties for large-scale use. Once fully optimized, the FeCl₃ cathode could be key to unlocking a future of cheaper, more efficient batteries, both for electric vehicles and large-scale energy storage systems.

“This technology has the potential to disrupt the battery industry,” Chen said. “It can provide a more sustainable, affordable, and reliable energy storage solution, which will have a lasting impact on both EVs and renewable energy grids.”

Chen’s research has been published in Nature Sustainability, highlighting the cathode’s potential as a low-cost solution for all-solid-state lithium-ion batteries. Collaborators include Ting Zhu, Yuanzhi Tang, Jue Liu, and Shuo Chen.

CITATION: Zhantao Liu, Jue Liu, Simin Zhao, Sangni Xun, Paul Byaruhanga, Shuo Chen, Yuanzhi Tang, Ting Zhu, Hailong Chen. “Low-cost iron trichloride cathode for all-solid-state lithium-ion batteries.” Nature Sustainability.

Subtly charming pop culture geek. Amateur analyst. Freelance tv buff. Coffee lover