Tetra Pak has always had sustainability at its core, dating back to 1951 when founder Ruben Rausing introduced the first tetrahedron-shaped paper-based milk carton. His vision was simple yet profound: make food safe and available everywhere. Today, this mission has evolved to include a strong focus on environmental sustainability.

“Ruben Rausing once said that a package should save more than it costs,” says Vikas Ahuja, Tetra Pak’s Sustainability Director. “We apply this principle to our social and environmental impacts, considering not just the cost of the package but its overall benefit to society and the planet.”

Tetra Pak collaborates with a range of companies to provide innovative processing and packaging solutions, particularly for the food and beverage industries. Their work with ready-to-drink (RTD) coffee beverages is a prime example of their commitment to minimizing environmental impact.

One of their major initiatives involves creating a circular system for their paper-based cartons, which are fully recyclable. The wood fiber in Tetra Pak products is a renewable resource, perfect for making items like serviettes, tissues, and cardboard boxes.

“In Australia and New Zealand, we’ve teamed up with startup saveBOARD,” Vikas explains. “They transform food and beverage cartons, coffee cups, and similar items into sustainable building materials akin to plywood. The process involves shredding the cartons and pressing them in an industrial sandwich press, with no need for chemicals or glues.”

In Australia, container deposit schemes accept RTD coffee cartons, making it easier for consumers to recycle. saveBOARD then turns these into building materials like ceiling tiles and wall panels. Tetra Pak aims to extend this system, helping cafés and RTD coffee producers ensure all their cartons are recycled.

“For instance, milk distributors deliver crates of Tetra Pak-packed milk and plant milk, then pick up the empty crates,” Vikas says. “We want to facilitate a system where these distributors end the day with vans full of empty cartons ready for recycling.”

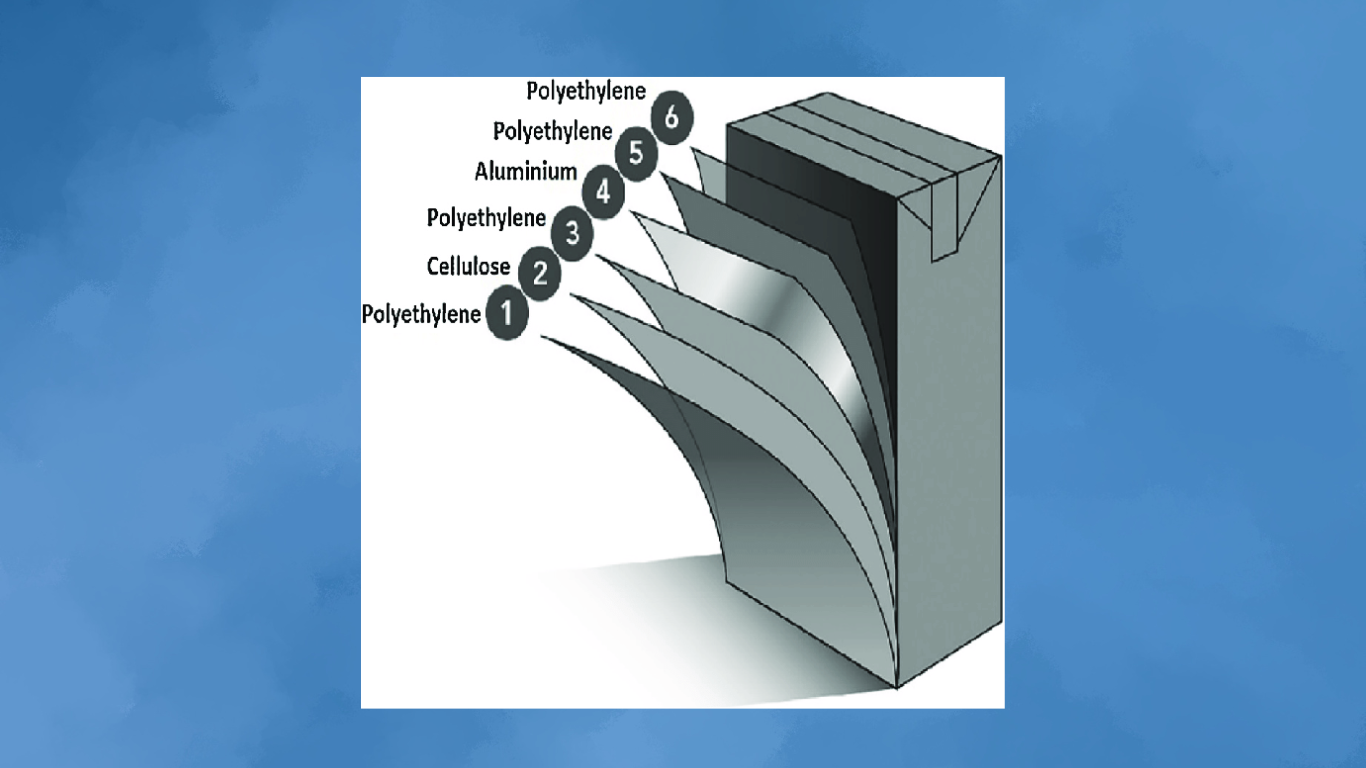

But recycling isn’t Tetra Pak’s only focus. They’re also continuously improving the materials in their products, aiming to increase the renewable content and reduce reliance on fossil-fuel-derived plastics. “We’re working on eliminating aluminum foil from our packs and developing a fiber-based barrier to ensure long shelf life without the need for refrigeration or preservatives,” Vikas adds.

As Tetra Pak enhances its eco-friendly credentials, more coffee brands are partnering with them for their RTD beverages. Tetra Pak collaborates with these brands to research, develop, test, and launch products.

“The process starts with consumer insights and trends,” says Michael Grigg, Tetra Pak Communications Manager. “We then work with clients on their innovation journey, considering optimal pack size, shape, cap design, and ensuring the best design outcomes. The Tetra Prisma® Aseptic Edge, with its DreamCap designed for optimum mouthfeel, is a great example.”

In the U.S., Tetra Pak worked with Wandering Bear Coffee to develop a range of cold brew family-size cartons and portion packs. “Wandering Bear summed up our approach perfectly: ‘nothing makes us happier than finding that beautiful intersection of functionality and sustainability, where user-friendly meets eco-friendly,’” Michael notes.

Tetra Pak sees huge potential in the Australian RTD coffee market and encourages both established and new brands to explore how they can support their innovation journey from concept to commercialization.

Subtly charming pop culture geek. Amateur analyst. Freelance tv buff. Coffee lover